A retarder is a device used to augment or replace some of the functions of primary friction-based braking systems, usually on heavy vehicles. Retarders serve to slow vehicles, or maintain a steady speed while traveling down a hill, and help prevent the vehicle from “running away” by accelerating down the hill.

Since their effectiveness decreases as vehicle speed decreases, they are typically unable to bring moving vehicles to a complete stop. They are usually used as an additional “assistance” to slow vehicles, with the final braking done by a conventional friction braking system.

Their service life is extended as the friction brake is used less, especially at higher speeds, and the fact that those vehicles’ brakes are air-actuated contributes to air pressure conservation.

Please continue reading for more information.

What Is A Retarder?

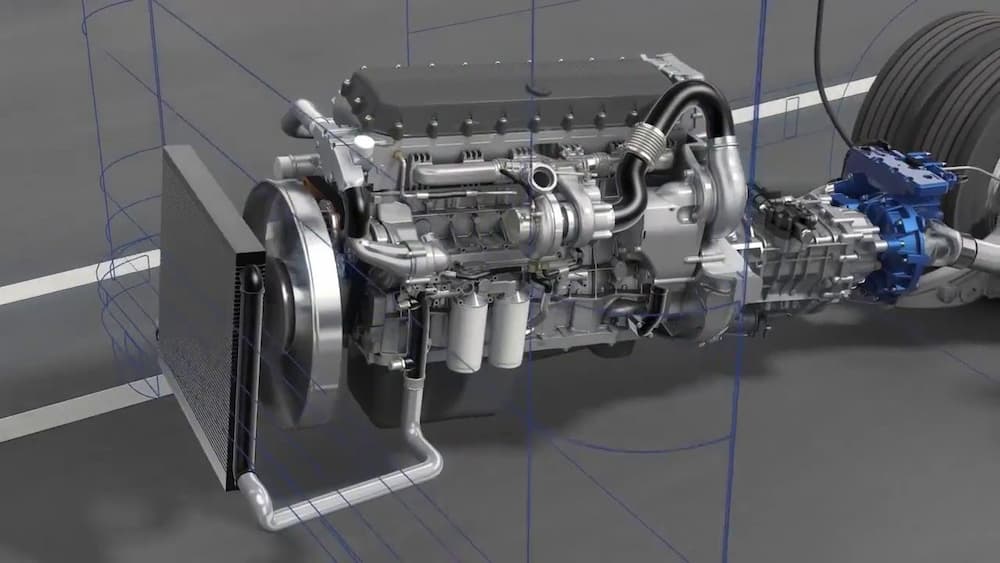

Retarders are used to further enhance commercial vehicles’ braking performance. Like engine brakes, they are wear-free continuous brakes. Retarders relieve the service brake and increase the active safety and cost-effectiveness of commercial vehicles. Retarders are installed in a commercial vehicle’s drive train.

How Does Retarder Work?

Some of the kinetic energy of the vehicle is transformed into heat by them. There are two types of retarders: primary retarders, which depend on engine speed and are installed between the engine and transmission, and secondary retarders, which depend on engine speed and are installed between the transmission and drive axle. After operation and structure, a further distinction is made between hydrodynamic retarders (hydrodynamic brakes) and electrodynamic retarders. The majority of modern forward control trucks use hydrodynamic secondary retarders. The braking effect depends on vehicle speed.

Why Retarders Are So Important To You

Retarders are devices that help a truck stop completely without using its friction brakes on its wheels or to assist those brakes in doing so. This is how we came to understand what they are and how they work on trucks.

You may be a truck driver, but have you ever thought to ask yourself why these retarders are so crucial? What makes them one of the things that no truck driver should survive without and so irreplaceable? You really need to understand the significance of these brake retarders, so let’s go into more detail.

Getting your driving test pass is necessary if you are a new truck driver. The likelihood of failure is extremely high if you don’t know what a retarder is.

Consider climbing a steep hill and then descending it while a truck is loaded with heavy cargo.

You decide to slam on the brakes as a result, but the trailer simply swerves to one side, seriously injuring or even killing you.

Or in another scenario, the truck’s brakes get too hot from use, it loses the ability to stop, and you rear-end someone or end up in a ditch. Both of these scenarios have the potential to be dangerous or even fatal.

For this reason, brake retarders were developed. when approaching a steep downhill road, to reduce the momentum of the car.

With no need for you to apply any brake pressure, the brake retarder will handle this task and gradually slow down the truck.

Because of this, you should be aware of the type of brake retarders you have on your truck and use them appropriately. See more about What Is A Runaway Truck Ramp?

Types Of Retarders On A Truck

Now that we have discussed what retarders are on trucks, we can move on to learning more about the different types of retarders that are on trucks.

Retarders come in a variety of forms and are utilized worldwide. Some of them are ridiculously straightforward, while others require a lot of explanation. But we’ll make sure to give you the best response possible to these queries.

We will briefly discuss each of these types in the chapters that follow. But after that, we’ll go over them in greater detail and gain a much better understanding of how they operate. So let’s get started.

Exhaust Retarder

Retarders on a truck are now something we are aware of. Let’s now examine the first type of retarder that is applied to trucks the most frequently.

And the exhaust retarder falls under this category. additionally called the exhaust brake. So how does the exhaust cause your car to stop?

There are techniques diesel engines employ to reduce the flow of exhaust gases, but doing so slows down the engine’s operation. The vehicle also slows down as a result of slowing the crankshaft’s rotation.

These retarders are among the most effective and straightforward types available. We will go into greater detail about this type’s operation and the reasons it is so helpful later on. We now know what truck retarders are. Let’s now discuss the second category of retarder.

Jake Brake

We now understand what a truck’s retarder is; let’s look at the second kind of available retarders. The Jake brake retarders are shown here. Then what exactly is a Jake brake retarder?

The previous type we discussed is similar to a Jake brake retarder. They are both engine decelerators. Consequently, they lower the engine’s RPM. However, the ways in which each of these types accomplish this vary. The previous did this by preventing gases from escaping from the exhaust, whereas the Jake brake takes a different approach.

In particular, this system is tinkering with the exhaust valves. It does this by opening the valves just as the compression stroke is about to end, releasing the compressed gas that has been trapped in the cylinders, which slows the car down. If you ask me, it’s a pretty clever design. We will go into greater detail about this design and its operation later on. Let’s now move on to the following system.

Hydraulic

We already know what truck retarders are, so let’s look at the next type of truck retarder, the hydraulic retarder.

As we mentioned, a torque converter and a hydraulic retarder are somewhat comparable. Typically, the vehicle’s driveshaft and transmission are where this part is mounted.

Hydraulic fluid is therefore pumped into this component to provide stopping power, and the fluid then acts as a resistance to the gear’s rotation. The hydraulic fluid creates a drag that is viscous in order to lessen the spinning motion. This kind of retarder is frequently used on buses because it works.

The good thing about this retarder is that you frequently can’t hear it because of how quiet it is. Hence, it is much more practical than the first two types that we previously discussed.

Electric

So now that we are aware of what truck retarders are, let’s look at the final type of truck retarder that is available. And this is the electric version of a retarder.

When it comes to where they are mounted, electric retarders and hydraulic retarders are very similar. Similar to the driveshaft and transmission, it is mounted there.

The use of electromagnetic induction by this retarder to produce a retarding force is the only distinction. Although less common, there are still many trucks out there that can use these retarders. But why is it important to understand what truck retarders are and how they differ from one another? Let’s go into more detail about this now.

Why You Should Know All These Types Of Truck Retarders

Retarders on a truck are now something we have learned about, along with the various types that are available. We can now discuss the importance of this knowledge for you. How come it’s so important? Let’s go into more detail in the paragraphs that follow and see why this is important.

Because you need a CDL driver’s license to operate a truck, you should be familiar with the types, functions, and requirements of retarders.

You simply need to be aware of this information if you decide to obtain a CDL driver’s license. Since how are you going to drive a semi-truck if you don’t know what an exhaust brake or a Jake brake is?

In order to operate a commercial vehicle with this kind of equipment installed, you really need to know this information.

If you don’t know how to use these features, you risk crashing if you try to descend a steep hill without knowing how to do it and damaging your standard brakes.

Being familiar with these types of brakes is another reason why everyone should know about them. It didn’t hurt anyone to have a little extra information. You might eventually decide to sign up for a CDL. Therefore, being aware of this beforehand will help you save a ton of time when learning how to prepare for these exams. But enough on that.

In the subsequent chapters, let’s examine how these brakes function and find out the answers to some frequently asked questions about them. We will primarily concentrate on engine braking, which includes the exhaust brake and the Jake brakes, and learn more about their characteristics and mode of operation.

Engine Braking Systems

As we previously mentioned, now that we know what truck retarders are, we can continue to learn more about engine braking systems. Electric and hydraulic systems are not covered in this article. only those that the engine uses. which are the Jake brakes and exhaust brakes. We will discover how they operate and their key characteristics. So, keep reading if you’re interested in learning more.

What Are Retarders On A Truck: What Is Exhaust Brake

As a result of what we’ve learned about truck retarders, we can now move on to a thorough discussion of the first kind of brake retarder. specifically the exhaust brake.

What then does the exhaust brake do? The hot side of the engine’s turbo is where this unique brake is located. This indicates that it is situated directly between the car’s turbo and exhaust.

As you can see, this system is typically installed on applications that use turbo diesel engines. Right next to the hot side of the turbo, you will see a large hump that is the exhaust brake.

It is even more straightforward and organized in some applications. Modern applications for this type of brake are more compact and simplified in terms of engineering. What about the way an engine’s exhaust brake functions?

What Are Retarders On A Truck: Jake Brake Meaning

After learning about truck retarders, let’s discuss the second and most widely used type of brake retarder. And that is the Jake brake.

Jake brakes are not a brand-new concept. Clessie Cummins was their inventor, and Jacobs Vehicle Systems was the first to put them into production in 1965. Jake Brakes became their moniker as a result.

Due to the fact that they essentially alter the engine’s compression, these brakes are also referred to as compression brakes. Trucks frequently have these brakes. But the problem with these brakes is that they have some restrictions, which we will cover in more detail later in the article.

But how does this kind of brake actually operate? When you most need this, what causes all the magic and your truck to stop? In the chapters that follow, we’ll go into more detail about this and examine the brakes’ mode of operation.

The Jake Brake System: How Does It Work?

Compression brakes, as we’ve already mentioned, are used on the Jake. This implies that they adjust the engine’s compression to stop it. So, let’s explain how they function.

The car continues to move forward when the driver takes their foot off the gas pedal. The Jake brakes, also known as compression brakes, are now in use.

Upon activation, this system opens the cylinder exhaust valves. only up until a certain point. Exactly at that point, the compression stroke comes to an end.

In the cylinders, compressed gas had been trapped until this action. In essence, the compressed air acting as a spring to push the piston downward is produced during the compression stroke. Additionally, this action slows the crankshaft’s movement and helps the engine lose momentum. the process of making the vehicle stop.

Furthermore, stopping power is excellent thanks to these Jake brakes. However, given that we now understand what truck retarders are, we will discuss some of their limitations in the following chapters.

Jake Brake Sound

Let’s discuss another intriguing topic, namely the legality of these types of brakes, now that we have learned how the Jake brakes function and what retarders on a truck are.

If you didn’t know, there are signs prohibiting engine braking in many places across the nation. In light of this, why is engine braking prohibited in populated areas and why is this actually the case?

Well, the sound is the main culprit. Both Jake brakes and exhaust brakes produce noise.

Everyone really despises the brakes, particularly the Jake brakes. primarily because the sound these brakes make when you step on them sounds like a heavy machine gun is being fired. Additionally, your ears will not find this to be comfortable. No, sir. Jake brakes are so bad, especially if you live close to a busy road, that it feels like the sky is falling on your head and the air force is bombing your home.

Therefore, there are numerous signs posted across the nation that read “No Jake Brakes Within City Limits.” You must only use them in an emergency if you use them in the city otherwise you risk receiving a hefty fine.

Faqs

Here are some frequently asked questions that will be addressed.

What Are Retarders?

Retarders are merely auxiliary non-friction brake aids. As you decelerate, they assist your truck in stopping. It is much better to use retarders so you can still get to the truck stop without running the risk of overheating your main brakes.

What Do Jake Brakes Do?

Simply put, a Jake brake is an engine brake. Another name for it is a compression brake. When this type of brake is engaged, it releases the compressed air that has been trapped in the cylinders by opening the exhaust valves just as the compression stroke is about to end. Your truck comes to a stop as a result.

What Means Jake Brake?

Jake brake is a specialized brake made to reduce engine momentum. Additionally, it is referred to as a compression brake. Because the original manufacturer of these brakes was a company by the name of Jacobs Vehicle Systems, it is also known as the Jake brake.

Not Using The Engine Brake Means What?

This means that trucks are not permitted to use engine braking in the area because this kind of braking generates a lot of noise that is upsetting to the nearby residents.

What Means Engine Brake Sign Not Present?

The area is not permitted to use engine braking, according to this sign. And by engine braking, we mean applying Jake brakes or exhaust brakes. This is true because of how loud these brakes are.

How Come Engine Braking Is Banned?

Due to how noisy it is, it is restricted in many places. When Jake brakes, it sounds like someone is firing a powerful machine gun. For those who live nearby, this can be very annoying.

Conclusion

Friction-based braking systems are susceptible to “brake fade” when used extensively for continuous periods, which can be dangerous if braking performance drops below what is required to stop the vehicle – for instance if a truck or bus is descending a long decline. Due to this, such heavy vehicles frequently have an additional, non-friction-based system installed.

Retarders can be used in railway systems as well as in vehicles on the road. The British Advanced Passenger Train (APT) prototype used hydraulic retarders to enable the high-speed train to stop in the same distance as conventional lower speed trains because a pure friction-based system was not practical.

Regarding your reading, I thank you.